-

Optimizing Heating Efficiency in Ultrasonic Cleaning Machines: Professional Insights

Optimizing Heating Efficiency in Ultrasonic Cleaning Machines: Professional Insights

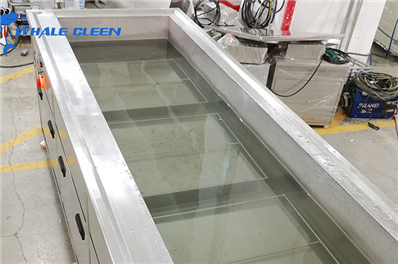

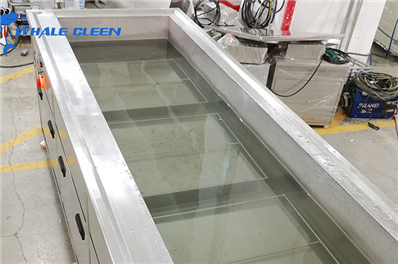

Ultrasonic cleaning machines are widely used in various industries for their effectiveness in removing contaminants from objects through the use of high-frequency sound waves. One crucial aspect of ultrasonic cleaning machines is their ability to maintain

-

Why Do People Use Ultrasonic Cleaners? The Ultimate Guide to Ultrasonic Cleaning Technology

Why Do People Use Ultrasonic Cleaners? The Ultimate Guide to Ultrasonic Cleaning Technology

In today's world of advanced cleaning technology, ultrasonic cleaners have become increasingly popular across various sectors. But what drives people to choose these sophisticated cleaning devices? The answer lies in their unparalleled cleaning capabi

-

How to Choose the Right Power for Ultrasonic Cleaners: A Data-Driven Guide

How to Choose the Right Power for Ultrasonic Cleaners: A Data-Driven Guide

Shocking Fact: 60% of Ultrasonic Cleaners Waste Energy Due to Wrong Power Selection A factory lost$47,000/yearin electricity costs because their 30kW cleaner only converted15% of energyinto effective cavitation. Meanwhile, another plant damaged delicat

-

How to Properly Position an Ultrasonic Cleaner? Complete Placement Guide for Optimal Performance

How to Properly Position an Ultrasonic Cleaner? Complete Placement Guide for Optimal Performance

Proper placement of your ultrasonic cleaner significantly impacts its efficiency, safety, and longevity. Whether for home use or industrial applications, following correct positioning guidelines ensures maximum cleaning performance while preventing potent

-

How to Calibrate an Ultrasonic Cleaner: A Step-by-Step Guide to Performance Verification

How to Calibrate an Ultrasonic Cleaner: A Step-by-Step Guide to Performance Verification

Article Content 1. The Importance of Calibrating Ultrasonic Cleaners (Keyword Density Optimization) Calibrating ultrasonic cleaners is essential for maintaining performance and reliability: Cleaning Efficiency: Uncalibrated machines c

-

How to Adjust Temperature on Ultrasonic Cleaners: A Complete Guide

How to Adjust Temperature on Ultrasonic Cleaners: A Complete Guide

Studies show that proper temperature control can improve cleaning efficiency by up to 40% and extend equipment life by 2-3 years. This guide will walk you through the steps to master temperature adjustment on your ultrasonic cleaner. 1. Understanding T

-

How to Disable Heating in Ultrasonic Cleaners: A Comprehensive Guide

How to Disable Heating in Ultrasonic Cleaners: A Comprehensive Guide

I. Reasons to Disable Heating 1. Application Scenarios Temperature-sensitive materials: Plastics (deformation risk above 50°C) Biological samples (prot

-

Why Don't Ultrasonic Cleaners Use Aluminum? Scientific Analysis and Practical Insights

Why Don't Ultrasonic Cleaners Use Aluminum? Scientific Analysis and Practical Insights

Ultrasonic cleaners are widely used in industries, laboratories, and households for their ability to remove contaminants from intricate surfaces. However, one notable observation is that these devices rarely use aluminum in their critical components, such

-

What Solutions Can Be Added to Ultrasonic Cleaners? A Professional Guide

What Solutions Can Be Added to Ultrasonic Cleaners? A Professional Guide

Ultrasonic cleaners use high-frequency sound waves to generate cavitation bubbles that clean surfaces by dislodging contaminants. While the physical action of the sound waves is highly effective, adding the right solution can significantly enhance cleanin

-

Innovation in Cleaning: The Industry Leadership of Ultrasonic Cleaning Machines

Innovation in Cleaning: The Industry Leadership of Ultrasonic Cleaning Machines

In the quest for efficiency, precision, and sustainability, ultrasonic cleaning machines have emerged as a game-changer in the cleaning industry. Leveraging the power of sound waves to achieve unparalleled cleanliness, these machines have carved out a lea

-

How Ultrasonic Cleaning Machines Improve Production Line Efficiency

How Ultrasonic Cleaning Machines Improve Production Line Efficiency

Introduction In modern manufacturing and production environments, efficiency is paramount. Achieving high productivity while maintaining superior product quality requires advanced tools and methodologies. Ultrasonic cleaning machines have become an ess

-

Ultrasonic Cleaning Machines: Perfect Synergy with Advanced Manufacturing

Ultrasonic Cleaning Machines: Perfect Synergy with Advanced Manufacturing

Advanced manufacturing, characterized by the integration of cutting-edge technologies and optimized production processes, demands high levels of precision and efficiency. Ultrasonic cleaning machines, known for their ability to clean complex parts and del

Optimizing Heating Efficiency in Ultrasonic Cleaning Machines: Professional Insights

Optimizing Heating Efficiency in Ultrasonic Cleaning Machines: Professional Insights

Why Do People Use Ultrasonic Cleaners? The Ultimate Guide to Ultrasonic Cleaning Technology

Why Do People Use Ultrasonic Cleaners? The Ultimate Guide to Ultrasonic Cleaning Technology

How to Choose the Right Power for Ultrasonic Cleaners: A Data-Driven Guide

How to Choose the Right Power for Ultrasonic Cleaners: A Data-Driven Guide

How to Properly Position an Ultrasonic Cleaner? Complete Placement Guide for Optimal Performance

How to Properly Position an Ultrasonic Cleaner? Complete Placement Guide for Optimal Performance

How to Calibrate an Ultrasonic Cleaner: A Step-by-Step Guide to Performance Verification

How to Calibrate an Ultrasonic Cleaner: A Step-by-Step Guide to Performance Verification

How to Adjust Temperature on Ultrasonic Cleaners: A Complete Guide

How to Adjust Temperature on Ultrasonic Cleaners: A Complete Guide

How to Disable Heating in Ultrasonic Cleaners: A Comprehensive Guide

How to Disable Heating in Ultrasonic Cleaners: A Comprehensive Guide

Why Don't Ultrasonic Cleaners Use Aluminum? Scientific Analysis and Practical Insights

Why Don't Ultrasonic Cleaners Use Aluminum? Scientific Analysis and Practical Insights

What Solutions Can Be Added to Ultrasonic Cleaners? A Professional Guide

What Solutions Can Be Added to Ultrasonic Cleaners? A Professional Guide

Innovation in Cleaning: The Industry Leadership of Ultrasonic Cleaning Machines

Innovation in Cleaning: The Industry Leadership of Ultrasonic Cleaning Machines

How Ultrasonic Cleaning Machines Improve Production Line Efficiency

How Ultrasonic Cleaning Machines Improve Production Line Efficiency

Ultrasonic Cleaning Machines: Perfect Synergy with Advanced Manufacturing

Ultrasonic Cleaning Machines: Perfect Synergy with Advanced Manufacturing